WASTE HEAT RECOVERY

Industrial applications

The potential of recovering industrial waste heat is huge. Around 60% of all generated energy in the industry is lost as waste, of which nowadays only a fraction is recovered.

RGS has selected the high temperature waste heat ranging from 700oC to 1500oC. The silicon based thermoelectric material produced by RGS has its optimal power output in this temperature range.

In particular a selection was made for heat recovery in the ferrous, non-ferrous and glass industry. These industries are well known for high temperature processes with a high level of waste heat.

Thermagy can be applied as "a smart heat exchanger" to generate electricity out of the waste heat and influence the heat flow from processes or product.

Steel

The steel industry is one of the industries with the highest CO2 emission globally, and a high energy consumption.

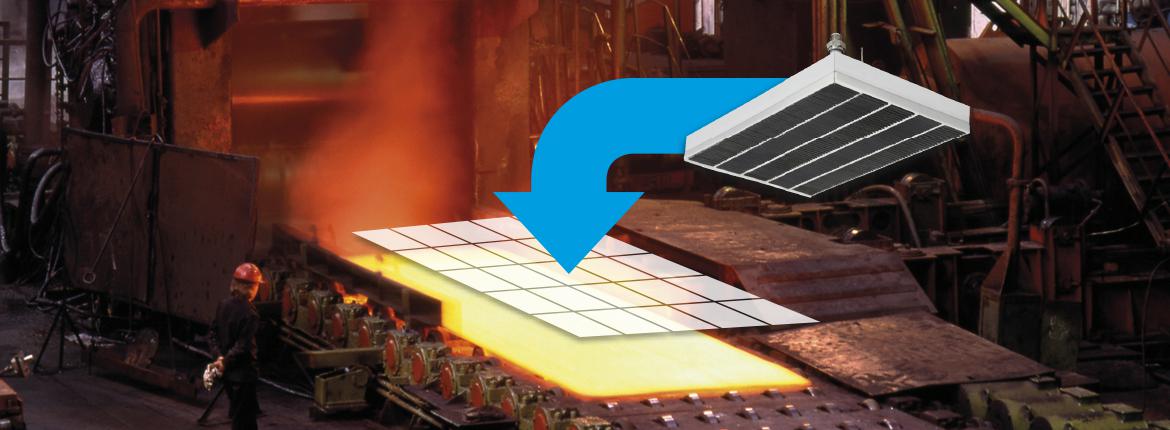

Implementation of the multifuntional Thermagy power panels can result in CO2 reduction, possibility to control the heat flow of processes, capture heat and generate power.

Thermagy power panels can be integrated in all high temperature (700-1500°C) production process steps, varying from the liquidus casting towards hot milling.

In the ferrous industry the focus is on controlling the heat flow of waste heat, and at the same time reducing the overall energy consumption.

Non-ferrous metals

Production and casting of non-ferrous metals are highly heat intensive processes, products and its gases contain a lot of heat energy. We are in discussions with Copper-, Alloys-, Nickel-, Manganese- as well as metal-recycling-industries to improve the value of Thermagy in the different stages of their processes.

In the non-ferrous industry the focus is on generating power, controlling the heat out of waste process heat, and to reduce overall energy consumption.

Glass

In the glass industry the focus is on generating heat and power out of waste process heat, to reduce overall energy consumption.

The high temperature and stability of waste heat sources in glass plants make waste heat recovery interesting. We already identified the following interesting hot spots for Thermagy to generate and convert waste heat in the glass production process:

- Feeder systems

- Flue gas channels ( oxy-fuel furnace )

- Workfurnaces ( working end, e.g flat glass )

- Regenerators ( regenerative furnace )

Potential Thermagy hot spots for maintaining a constant temperature are:

- Working end

- Refining furnace

- Feeder